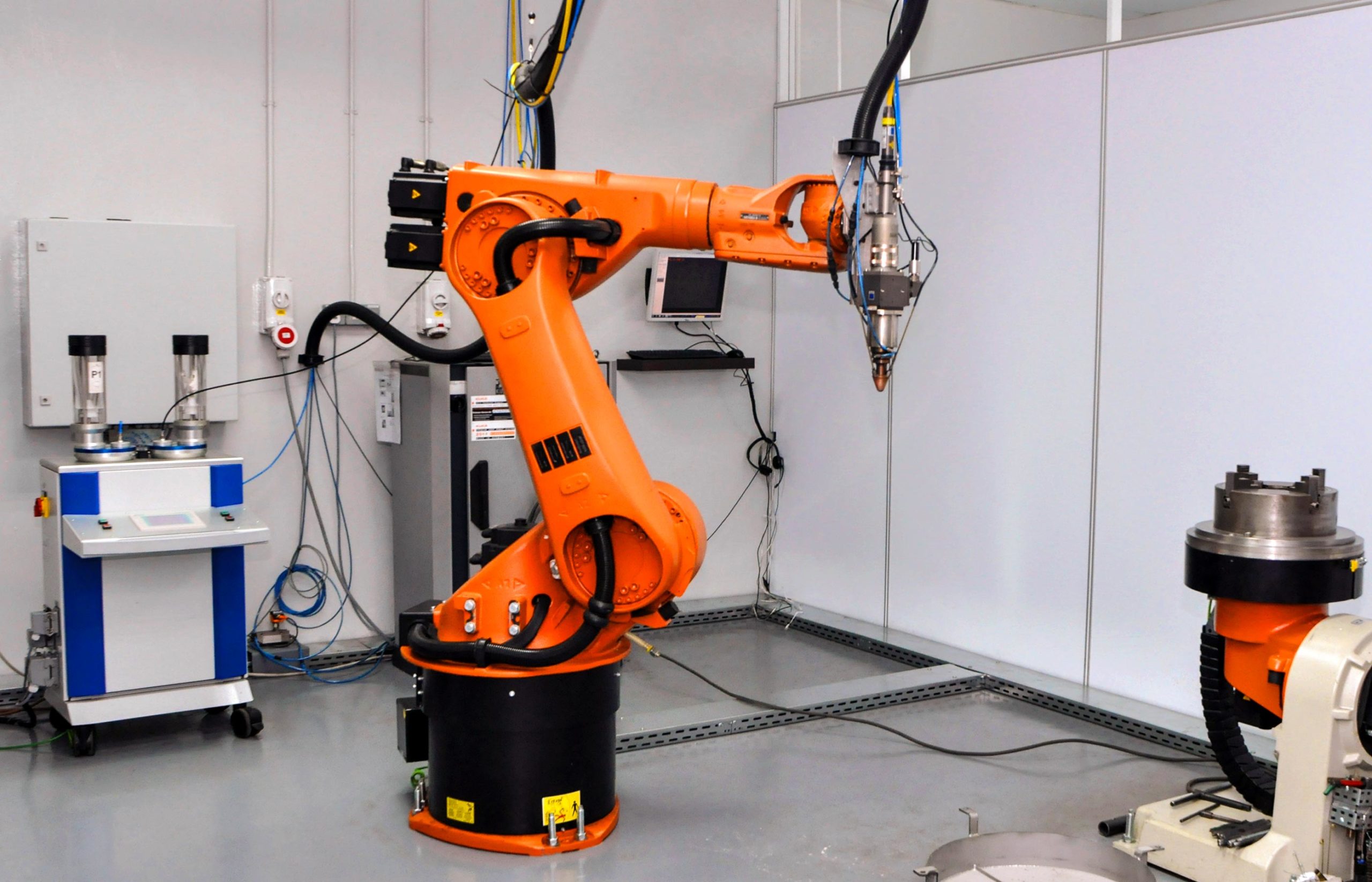

THE PROCESS

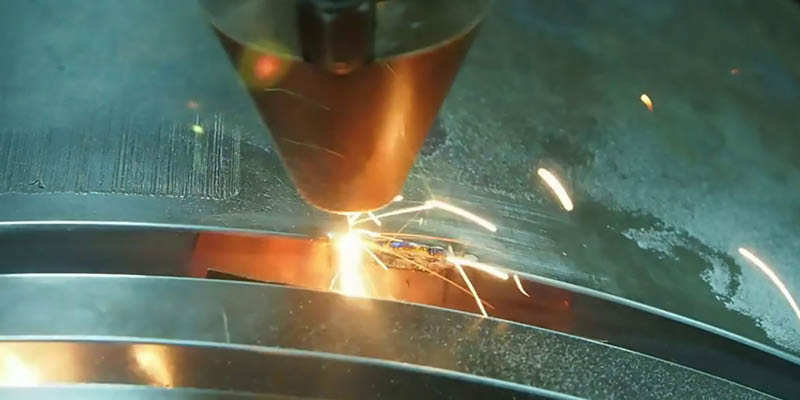

Laser powder cladding stands out as an advanced welding process, surpassing conventional methods on multiple fronts. Its superior precision and control enhance weld quality and consistency, while its versatility allows for the use of challenging materials. This process minimizes heat-affected zones and distortion, reducing the need for post-welding treatments. Notably faster than conventional welding, laser powder cladding is cost-effective, offering efficiency improvements without the expense of new components.

RESEARCH AND DEVELOPMENT

The industrial application of Laser Powder Cladding results from over 15 years of ongoing research and development by German Gall & Seitz Systems in collaboration with Trumpf and the Bremen Institute of Applied Beam Technologies. Originally applied to the marine sector, this cutting-edge technology now serves various industries, excelling in welding objects with high carbon content. Our technology has successfully reconditioned parts from diverse industries, contributing to a zero-claim policy.

Technical advantages include metallic bonding of layers, limited distortion, small heat-affected zones, low processing effort, and enhanced durability. Laser powder cladding, a superior alternative to conventional welding, offers precision, material flexibility, reduced heat zones, and expedited processes, proving cost-effective for efficiency improvement.

PRECISION AND ACCURACY:

• Enables highly precise material deposition.

• Achieves intricate designs with minimal material waste.

MATERIAL VERSATILITY:

• Accommodates a wide range of materials, including metals and alloys.

• Provides flexibility for diverse manufacturing and remanufacturing needs.

MINIMAL THERMAL DISTORTION:

• Localized heat input preserves substrate material integrity.

• Ensures components with superior mechanical properties and dimensional accuracy.

MULTI-MATERIAL CAPABILITIES:

• Facilitates the application of multiple layers.

• Allows for the creation of complex, multi-material structures.

RAPID SOLIDIFICATION RATES:

• Promotes fine microstructure formation.

• Improves material properties, particularly beneficial for heat-sensitive materials.

COST EFFICIENCY:

• Reduces material waste, optimizing costs.

• Minimizes repair costs and downtime, extending product life cycles.

ENVIRONMENTAL IMPACT REDUCTION:

• Contributes to a sustainable manufacturing process.

• Reduces overall environmental impact through optimized resource usage.

These advantages collectively position laser powder cladding as a valuable technology for enhancing efficiency, quality, and sustainability in the manufacturing and remanufacturing industry.